Aries Electronics / Larsen Associates

Test Sockets, Burn-In Sockets, IC Adaptors, Display Sockets, plus Standard & Custom Packaging Solutions

Test Sockets, Burn-In Sockets, IC Adaptors, Display Sockets, plus Standard & Custom Packaging Solutions

Test & Burn-in Sockets / IC Adapters "Correct-A-Chip™"/ High Temperature Sockets / Display Sockets / Contact US

Selection Guide, and Links to PDF DATA SHEETS

BGA sockets, LGA, CSP Sockets Chip Scale Test and Burn-in Sockets & BGA Adapters

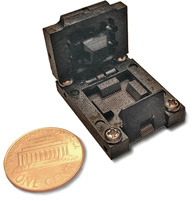

VERY SMALL FOOTPRINT - Device Size = from less than 1mm up to 6.5mm

VERY SMALL FOOTPRINT

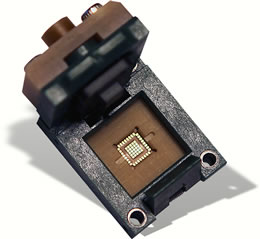

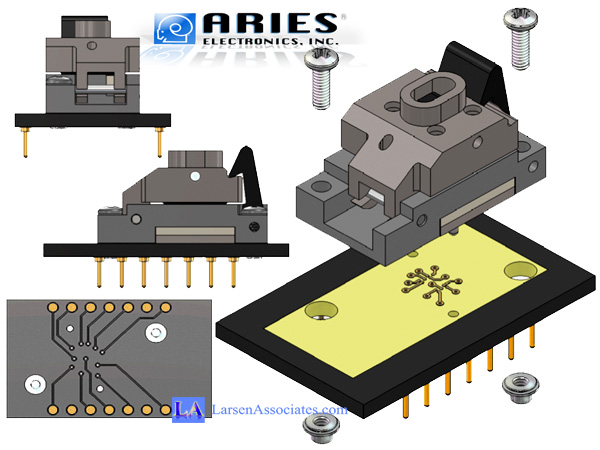

Very Small Footprint, CSP Micro BGA Socket

For Any SMT device, BGA or any other Contact style

- CSP Micro BGA Socket

- For Any SMT device, BGA or any other Contact style

- For 1 mm or less packages up to 6.5 mm packages

- Chip Scale to fit any package footprint

-"Fast, Economical, Cost Effective, <1Ghz to 18.5"

Pitch = .2 mm and larger

Device Size = 1mm or less up to 6.5mm

Application = For any SMT device

Test and burn in Socket for CSP,MicroBGA, DSP, LGA, SRAM, DRAM, Flash, etc..

From under 1GHz with versions available to 18.6 GHZ

Hold down = Clam Shell Lid no solder ,

Board mount = Spring contacts with screws to board

Cycles = greater then 500,000 cycles

Contact = springs

Body = UL94V-O /PEEK

Temperature = -55C TO 150C

Insertion Force/ Withdrawal force = 9-12g nominal 15g max

1GHZ or less = DATA SHEET # 23021.pdf

Over 1GHZ up to 18.5GHz = DATA SHEET # 24013.pdf

SMALL FOOTPRINT - Device Size = 7mm up to 13mm

SMALL FOOTPRINT

CSP Micro BGA Socket

For Any SMT device, BGA or any other Contact style

-For 1 mm packages up to 13 mm packages

-Chip Scale to fit any package footprint

-"Fast, Economical, Cost Effective, <1Ghz to 18.5"

Pitch = .2 mm and larger

Device Size = any package up to 13mm

Application = For any SMT device

Test and burn in Socket of CSP,MicroBGA, DSP, LGA, SRAM, DRAM, Flash, etc., From under 1GHz with versions available to 18.6 GHZ

Hold down = Clam Shell Lid no solder ,

Board mount = Spring contacts with screws to board

Cycles = greater then 500,000 cycles

Contact = springs

Body = UL94V-O /PEEK

Temperature = -55C TO 150C

Insertion Force/ Withdrawal force = 9-12g nominal 15g max

1GHZ or less = DATA SHEET# 23017.pdf

Over 1GHZ up to 18.5GHz = DATA SHEET # 24008.pdf

See Gallery 3

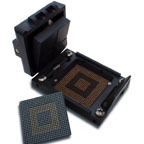

MEDIUM FOOTPRINT - Device Size = 14mm up to 27mm

MEDIUM FOOTPRINT

-For 14 mm packages up to 27 mm packages

-Chip Scale to fit any package footprint

-"Fast, Economical, Cost Effective, <1Ghz to 18.5"

Pitch = .2 mm or larger

Device Size = any package up to 27mm

Application =For any SMT device

Test and burn in Socket of CSP,MicroBGA, DSP, LGA,

SRAM, DRAM and Flash devices, etc., From under 1GHz with versions available to 18.6 GHZ

Hold down = Clam Shell Lid, no solder

Board mount = Spring contacts with screws to board

Contact = 4 point crown to ball, springs to board

Cycles = greater then 500,000 cycles

Body = UL94V-O /PEEK and or Ultem

Temperature = -55C TO 150C

Insertion Force/

Withdrawal force = 9-12g nominal on .5 to.75 mm pitch,17-20g on .8mm up

Data Sheets:

1GHZ or less = DATA SHEET# 23018.pdf

Over 1GHZ up to 18.5GHz = DATA SHEET # 24009.pdf

LARGE FOOTPRINT - Device Size = 28mm up to 40mm

LARGE FOOTPRINT

-CSP Micro BGA Socket

For Any SMT device, BGA or any other Contact style

-For up to 40 mm packages

-Chip Scale to fit any package footprint

-"Fast, Economical, Cost Effective, <1Ghz to 18.5"

Pitch =.2 mm or larger

Device Size =any package up to 40mm

Application =For any SMT device

Test and burn in Socket of CSP,MicroBGA, DSP, LGA, SRAM, DRAM,and Flash devices, etc.,From under 1GHz with versions available to 18.6 GHZ

Hold down =Clam Shell Lid, no solder

Board mount =Spring contacts with screws to board

Cycles =greater then 500,000 cycles

Body =UL94V-O /PEEK and or Ultem

Contact =4 point crown to ball, springs to board

Temperature =-55C TO 150C

Insertion Force/

Withdrawal force =9-12g nominal on .5 to.75 mm pitch,17-20g on .8mm up

Data Sheets:

1GHZ or less = DATA SHEET# 23019.pdf

Over 1GHZ up to 18.5GHz = DATA SHEET # 24011.pdf

EXTRA - LARGE FOOTPRINT - Device Size = 41mm up to 55mm

EXTRA - LARGE FOOTPRINT

For CSP Micro BGA Socket

For Any SMT device, BGA or any other Contact style

-For any package up to 55 mm packages

-Chip Scale to fit any package footprint

-"Fast, Economical, Cost Effective, <1Ghz to 18.5"

Pitch =.2 mm or larger

Device Size =27mm to 55mm

Application =For any SMT device

Test and burn in Socket of CSP,MicroBGA, DSP, LGA, SRAM, DRAM,and Flash devices, etc., From under 1GHz with versions available to 18.6 GHZ

Hold down =Clam Shell Lid, no solder

Board mount =Spring contacts with screws to board

Cycles =greater then 500,000 cycles

Body =UL94V-O /PEEK and or Ultem

Contact =4 point crown to ball, springs to board

Temperature =-55C TO 150C

Insertion Force/

Withdrawal force =9-12g nominal on .5 to.75 mm pitch,17-20g on .8mm up

Data Sheets:

1GHZ or less = DATA SHEET# 23020.pdf

Over 1GHZ up to 18.5GHz = DATA SHEET # 24012.pdf

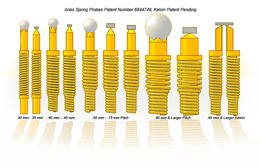

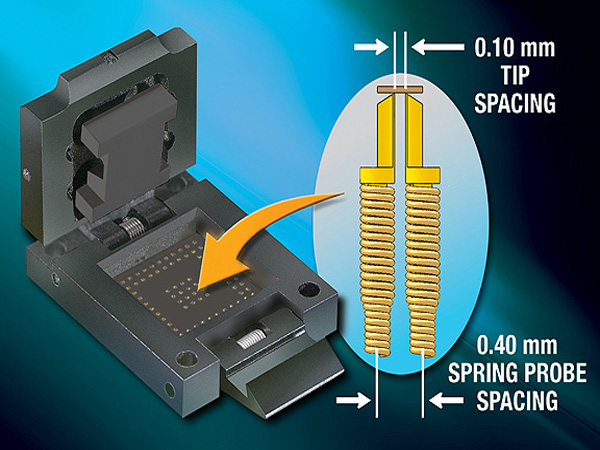

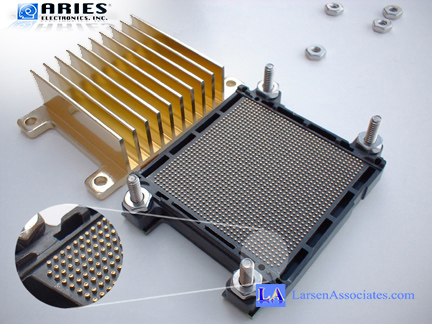

Aries Spring Probes - Now From 0.2mm pitch and up

Aries Spring Probes

for above test sockets 0.2 mm pitch & up

Compression spring probes:

heat treated Beryllium Copper Alloy.

Compression Spring Probe plating:

30u" min (0.75um) Gold per Mil-G-4QQ-N-290.

Durability:= 500,000 cycles min.

Contact Force:

= 16g per contact on 0.40 mm pitch,

= 25g per contact on 0.5 -0.75mm pitch

= 25 g per contact on .80mm pitch or larger

Operating Temp:

= -55C (min) to 150C (max);

-67F (min) to 302F (max).

Typical Avg Burn-In Temperature: = 150C max

Aries Chip Scale Test Sockets:

Spring Probes, Data Sheets, & Test Reports

See Gallery 5

CLICK here for More High Frequency RF Test sockets over 1 GHz

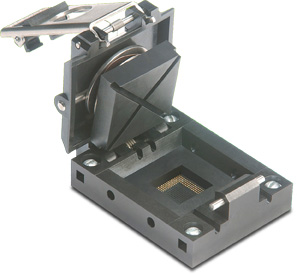

Kelvin Sockets

Kelvin Sockets: FEATURES

- Low resistance testing using dual independent Aries Kelvin spring probe technology per device pad for testing of MLF, QFN, LGA and other leadless devices.

- Any pitch device on 0.40mm pitch or higher

- Socket is easily mounted and removed to & from the test board due to solderless pressure mount compression spring probes which, are accurately located by two molded plastic alignment pins and mounted with four stainless steel screws

- The Au over Ni plated compression spring probes leave very small witness marks on the bottom surface of the device pads

- Small overall socket size/profile allows max. number of sockets per test board, while being operator friendly

- Kelvin Test Socket Contact System is available for any Aries CSP and Center Probe Test Sockets

- Pressure pad compression spring provides proper force against device and allows for height variations in device thickness

- Probe blade edge tip for cutting through solder oxide layers

- Signal path during test only 0.082 [2.08]

DATA SHEET # 23022.pdf

See Kelvin Sockets page

- CSP Hybrid Socket

- CSP Hybrid Socket

ZIF style socket using Aries solderless, gold-plated pressure mount Spring Probe

Pitch = .2mm and larger

Device Size = any size

Socket lid nests device into socket for a reliable connection

Appllication: Suitable for prototyping, test, or burn-in of CSP, BGA, BGA and LGA devices

Specifications:

Body Material: PEEK or TORLON

1dB Bandwidth: 1GHz (0.80mm pitch) (large probe)

Estimated Contact Life: 500,000 cycles

Compression Spring Probes: heat-treated Beryllium-Copper with 30µ min. [0.75µ] Gold per Mil-G-45204 over 30µ min.

[0.75µ] Nickel per SAE-AMS-QQ-N-290

Contact Force :

15g per contact on 0.30-0.35mm pitch

16g per contact on 0.40-0.45mm pitch

25g per contact on 0.50-0.75mm pitch

25g per contact on 0.80mm pitch or larger

Screws and Alignment Pins: Stainless Steel

Inserts: Brass Alloy per QQ-B-626, Tin-plated

Operating Temperature Range: -55ºC to 150ºC [-67º to 302º]

NOTE: Special lid designs and/or materials can be quoted

Socket easily located, mounted & removed from PCB

Signal path during test only 0.077 [1.96]

4-point crown insures “scrub” on solder oxides. Consult factory for other available probe styles

The gold over nickel plated compression spring probes leave very small witness marks on the bottom surface of the device solder balls

See Gallery 6

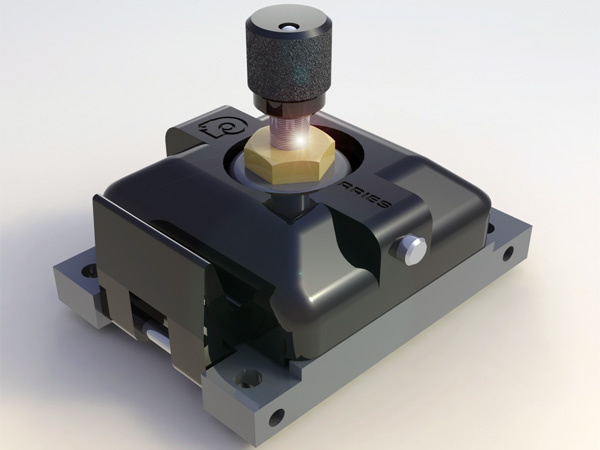

Adjustable "Z" Height Sockets:

Adjustable for Device Thickness Sockets:

For prototypes of a chip under development that will always have the same footprint, but may have the thickness of the package vary until the design is firmed up, or have a requirement to apply minimum force, and no more, such as with fragile ceramic chips or very thin devices.

Aries has developed a way of making the depth of the pressure pad adjustable, using a micrometer. Other variations include and optical pathway down the center of the adjuster. For Test & Burn-In of CSP, MicroBGA, DSP, LGA, SRAM, DRAM, QFN, PQFP, BGA, Flash Devices, etc..Any Surfance mount device. • Any pitch device on 0.30mm or larger. • Pressure mounting, no soldering required. • 4 Point crown insures scrub” on solder oxides. • Signal path during test only .077” (1.92mm) • Accommodates any package up to 27mm2. • Small overall socket size/profile allows maximum number of sockets per BIB and BIB’s per oven, while being operator friendly.

See Gallery 8

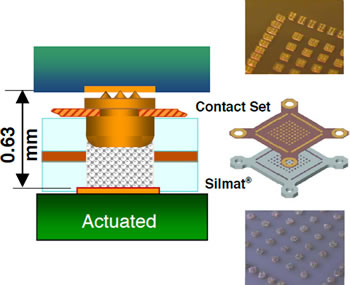

High Performance Elastomer Test Sockets:

Long-Life Hi-Frequency Sockets for BGA, LGA, QFN, MLCC, µBGA and Bumped Die Devices

Significant improvements to our high-performance contact system. Using our proven Interposer Elastomer Technology, the new CORE feature internally controls compression to ensure stability with extremely low resistance values and much longer contact element life.

Data Sheet # 24005.pdf

High-Temp 200°C CSP Burn-in & Test Sockets:

High-Temp (up to 200°C) CSP Burn-in & Test Sockets for BGA, LGA, QFN, MLCC, and Bumped Die Devices or Any Custom Machined Configuration – for high-frequency bandwidth, low inductance, and high-current applications in a reliable and durable socket housing

Data Sheet # 23026HT.pdf

High-Temp 200°C Universal PGA ZIF Burn-in & Test Sockets:

High-Temp (up to 200°C) Universal PGA ZIF Burn-in & Test Sockets – for any footprint on standard 8x8 to 21x21 grids

Data Sheet # 10004HT.pdf

High-Temp 250°C RF Test Sockets:

High-Temp (up to 250°C) RF Test Socket with Replaceable Contact Strips – for all peripheral-leaded devices including MLF, QFN, QFP with very low inductance

Data Sheet # 24001HT.pdf

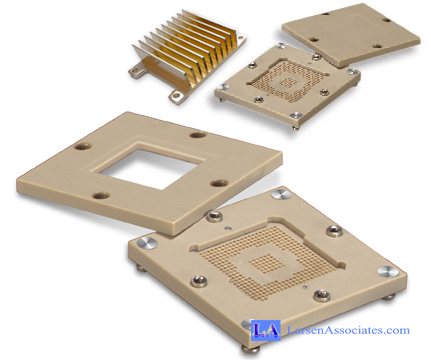

Custom Small or Very Large Array BGA & LGA & CSP Test & BI Sockets:

Custom BGA & LGA

Contact us with your needs.

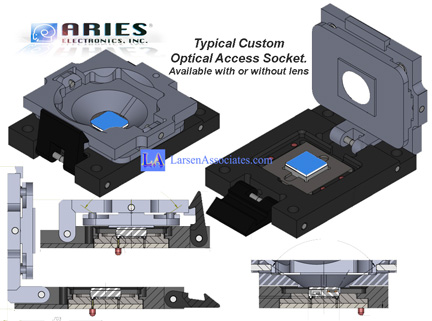

Optical or Open Top Access sockets:

FA Sockets:

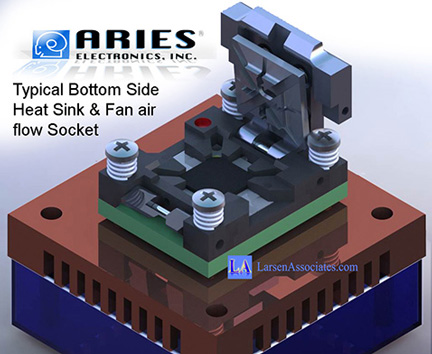

Thermal Test sockets:

Top or Bottom Side Heat Sinks & Heat Slug Sockets Test & Burn-in

Custom IC Socket Adapters and / or IC Adapters:

Also of Note:

- Aries makes standard IC adapters and Custom IC adaptors to suite your exact needs.

Custom Correct-A-Chip™Adaptor Sockets (Any Footprint to Any Footprint, Any Pin to Pin, Any Termination, 20 days), Correct-A-Chip© Adapters

Request a Custom Correct-A-Chip™Adaptor Quote

Or to Request a Quote by email, please include your company name and location, your contact information, description of your application, and your estimated annual quantity.

01/31/2024