|

"Aries, a world leader in test socket technology" |

|

|

||||||||||||

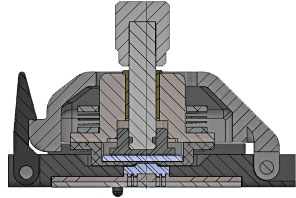

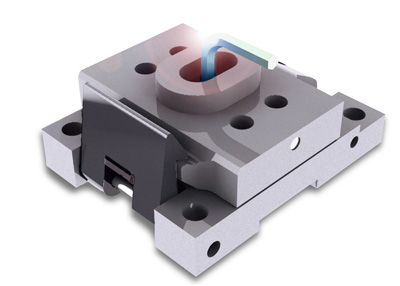

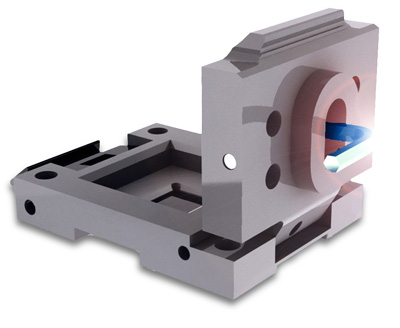

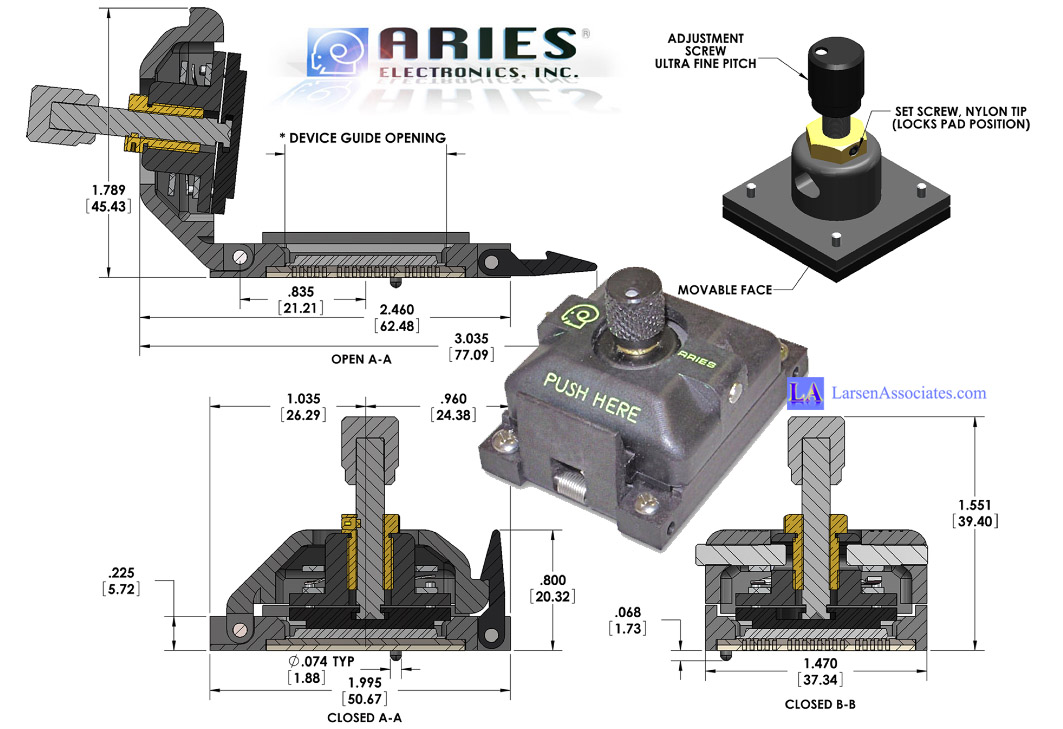

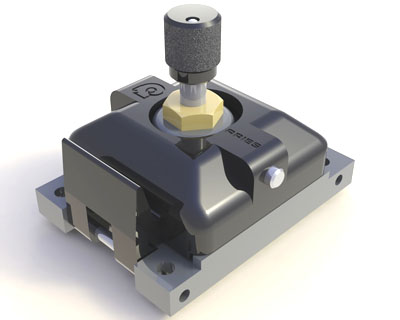

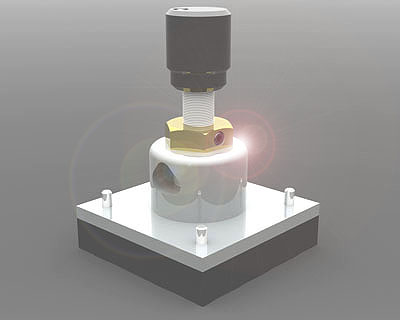

| The ADJUSTABLE Chip Scale Test Socket:........ Freedom of Range for different device thickness options, or device fragility. | ||||||||||||

| For prototypes of a chip under development that will always have the same footprint, but may have the thickness of the package vary until the design is firmed up, or have a requirement to apply minimum force, and no more, such as with fragile ceramic chips or very thin devices. | ||||||||||||

|

||||||||||||

|

Chip Scale Test Socket Test & Burn-In of CSP, MicroBGA, QFN, DSP, LGA, SRAM, DRAM, PQFP, Flash Devices, etc. Any SMT Device!

|

||||||||||||

|

Now available .3mm pitch and up, Spring Probe Test Sockets From Under 1GHz, to 18.5 Ghz

|

||||||||||||

|

• Features:

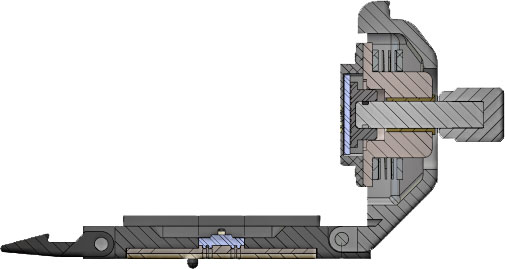

For prototypes of a chip under development that will always have the same footprint, but the thickness of the package will vary until the design is firmed up. Aries has developed a way of making the depth of the pressure pad adjustable, using a micrometer. Other variations include and optical pathway down the center of the adjuster. For Test & Burn-In of CSP, MicroBGA, DSP, LGA, SRAM, DRAM, QFN, PQFP, BGA, Flash Devices, etc..Any Surfance mount device. • Any pitch device on 0.30mm or larger. • Pressure mounting, no soldering required. • 4 Point crown insures scrub” on solder oxides. • Signal path during test only .077” (1.92mm) • Accommodates any package up to 27mm2. • Small overall socket size/profile allows maximum number of sockets per BIB and BIB’s per oven, while being operator friendly.

• Specifications:

• Molded socket components are UL94V-0 PEEK and/or Ultem. • 1dB Bandwidth at 1Ghz (0.80mm pitch) (large probe). • Estimated Contact Life: = 500,000 cycles. • Compression spring probes are heat treated Beryllium Copper Alloy with 30u” min. [.75um] Gold per Mil-G-45204 over 30u” min.[.75um] Nickel per QQ-N-290. • Contact Force = 9-12g per contact on 0.50 - 0.75mm pitch 17-20g per contact on 0.80mm pitch or larger. • Operating Temperature = -55°C (min.) to 150°C (max.); -67°F (min.) to 302°F (max.). • All Hardware is Stainless Steel. • Typical Burn-in Temperature = 125°C. Mounting Considerations: • Aries supplies (4) four #4-40 screws and tapped, insulated, backing plate for mounting. • Sockets must be handled with care when mounting or removing sockets to/from PCB. • Test board PCB diameter = .026” (0.66mm) (large probe) = .016” (0.40mm) (small probe)

|

||||||||||||

| basic DATA SHEET# 23018.pdf | ||||||||||||

| Back to top of page / Selection Guide / Large Photos / | ||||||||||||

| For more Test Sockets over 1 GHz, Click Here | ||||||||||||

|

|

|

|

|

Copyright © 1988, 2024 LARSEN ASSOCIATES

|

|

|

Open Position

Open Position